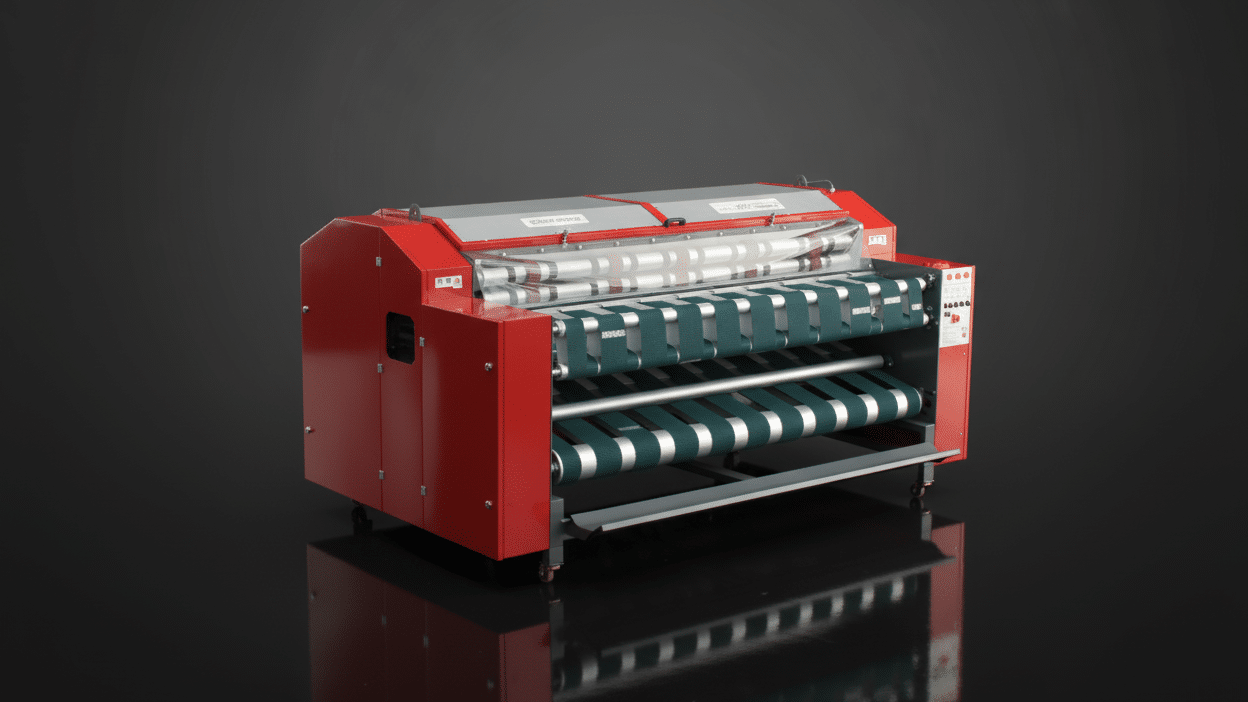

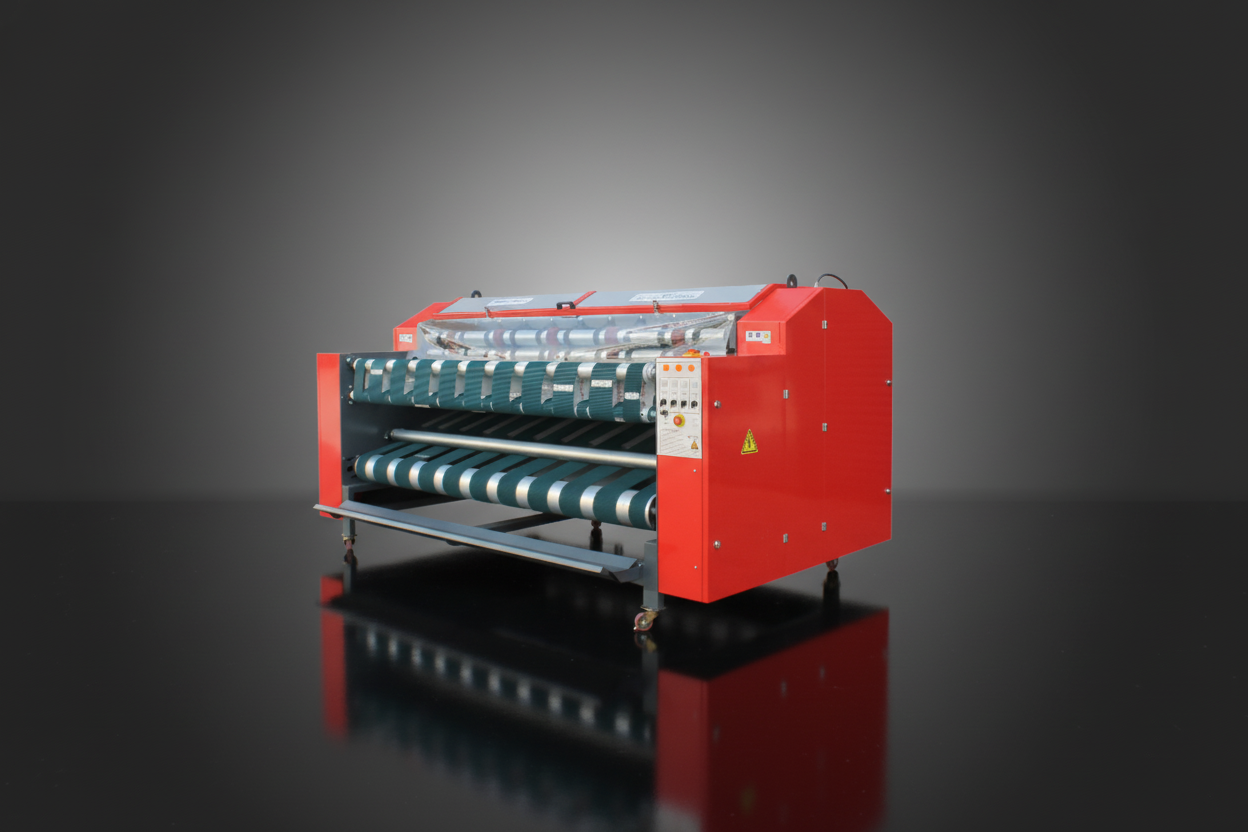

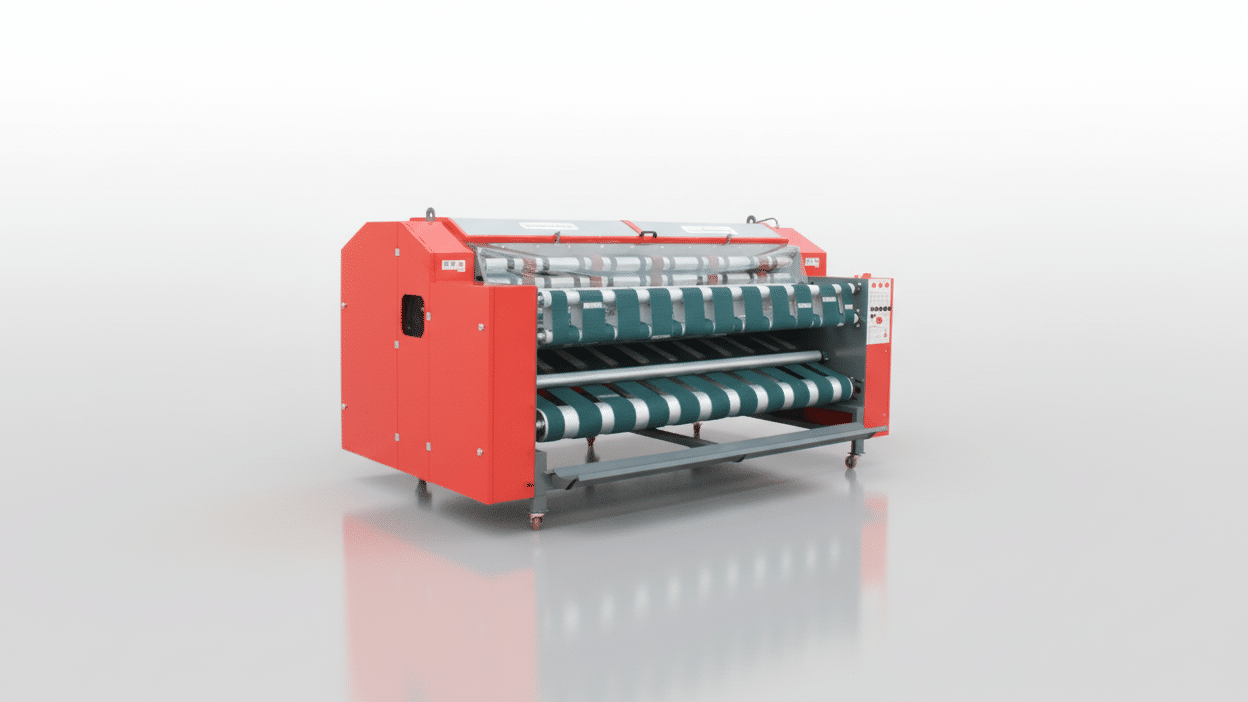

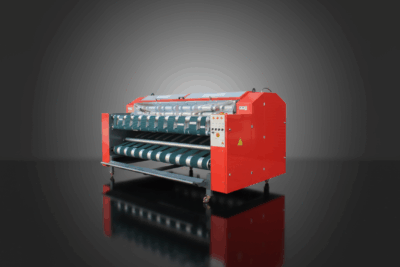

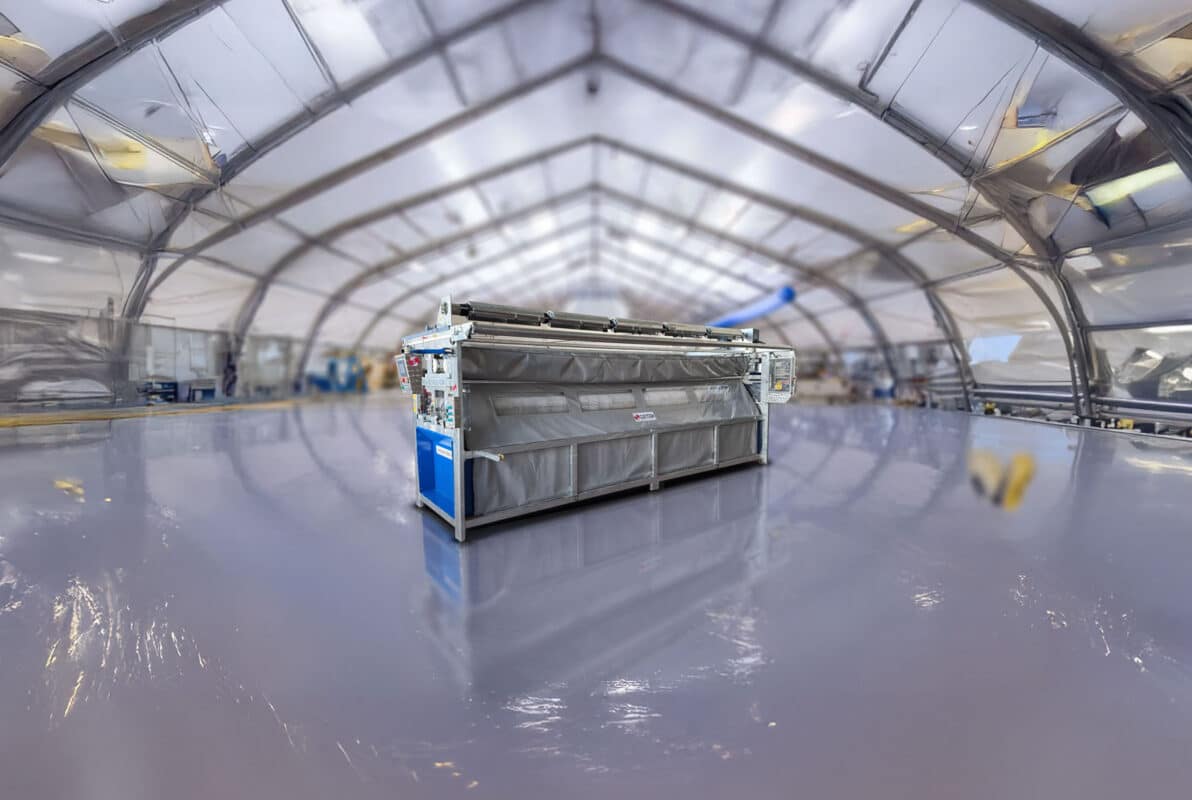

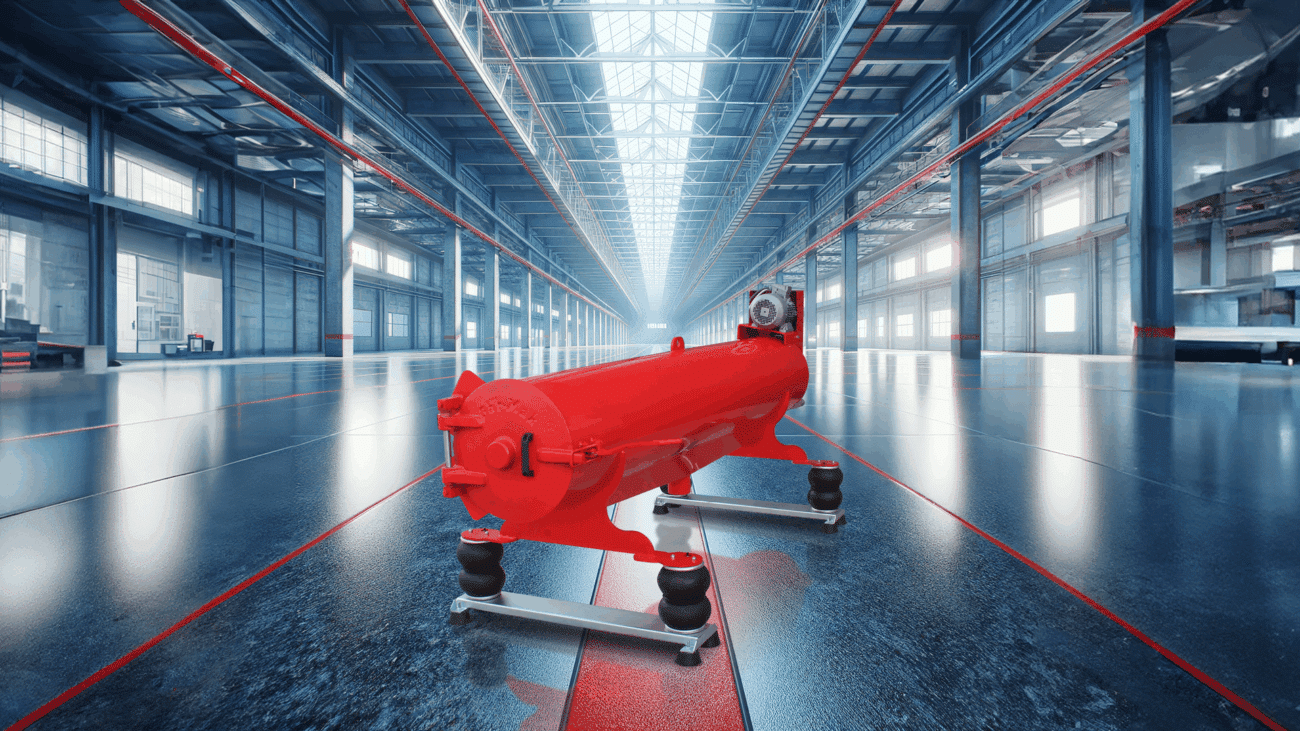

Beater Carpet Beating and Dust Removal Machine

✅ Deep cleaning performance – Mechanically loosens and removes embedded dust and solid particles.

✅ Reduced water and chemical consumption – Enhances detergent efficiency and improves washing performance.

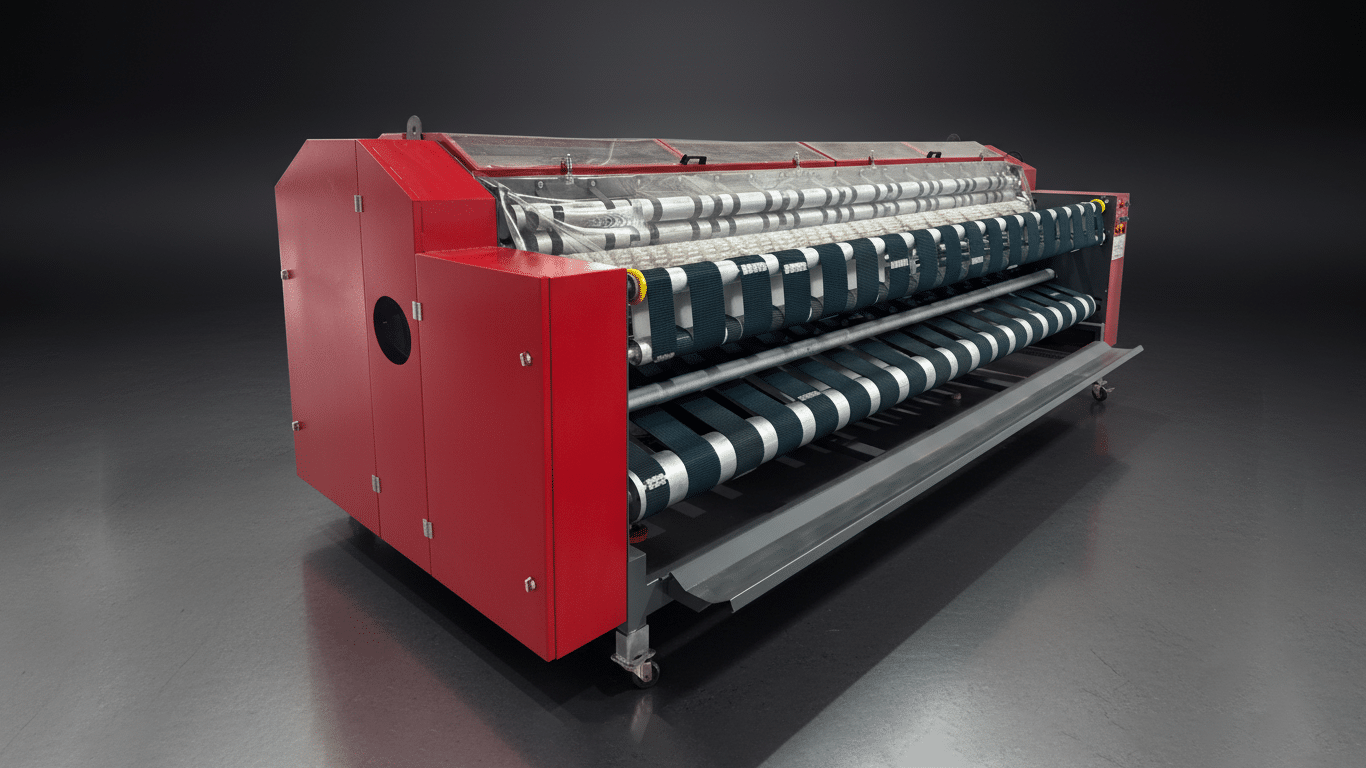

✅ 3×3 beating system (9 beaters) – Delivers maximum cleaning power without damaging carpet fibers.

✅ Front-feed / front-output ergonomics – Waist-level handling ensures operator comfort and easy use.

✅ Automatic roll-up system – Quickly and neatly rolls carpets, saving time and labour.

✅ Roller brush system – Completes final surface cleaning after the beating process.

✅ Vacuum fan + brush-belt system – Captures dust and automatically keeps the machine clean.

✅ Space-saving design – Can be positioned directly against the wall for efficient use of workspace.

✅ Optional adjustable belt speed – Allows optimal performance for different carpet types.

Pre-Wash Deep Preparation

Removes embedded dust and solid particles trapped deep within the carpet.

Enhances the catalytic efficiency of chemicals, delivering a more effective wash.

Reduces water consumption and ensures a more efficient washing cycle.

Loosens deep-settled dust that standard washing machines struggle to remove, enabling effortless extraction.

Powerful & Safe Beating Technology

A total of 9 beaters arranged in a 3×3 configuration creates a wave-motion effect for maximum performance.

Provides safe cleaning without damaging carpet fibers, extending the carpet's overall lifespan.

After the beating cycle, the roller-brush system removes any remaining surface residues.

User-Friendly Design

Front-feed / front-discharge operation at waist level ensures ergonomic use and minimizes operator fatigue.

Automatic carpet rolling feature improves speed, convenience, and workflow efficiency.

Wall-aligned installation enables significant space savings in the facility.

Hygiene & Cleanliness

The vacuum fan traps collected dirt and debris directly into the dust bag.

The brush-belt system performs continuous self-cleaning for the machine.

Optional adjustable belt-speed allows compatibility with different carpet types.

The Result

Thanks to our high-performance beating machine, carpets are thoroughly treated before washing, removing even the most persistent soils and maximizing overall washing efficiency.

Speed, hygiene, and efficiency all in one system.

| Feature | D4025S | D4032S | D5042S |

|---|---|---|---|

| Series | Professional | Professional | Professional |

| Belt Width (cm) | 250 | 320 | 420 |

| Dust Removal Speed (m/min) | 3 m/min | 3 m/min | 3 m/min |

| Vacuum Capacity (m³/h) | 3000 m³/h | 3000 m³/h | 3000 m³/h |

| Number of Beaters | 3×3 | 3×3 | 3×3 |

| Beating Speed (hit/min) | 1800 hit/min | 1800 hit/min | 1800 hit/min |

| Energy Consumption (kW/h) | 3 kW/h | 3 kW/h | 4 kW/h |

| Total Power (kW/h) | 7 kW/h | 7 kW/h | 8 kW/h |

| External Dimensions (cm) – W×D×H | 310 × 225 × 165 | 380 × 225 × 165 | 480 × 225 × 165 |

| Weight (kg) | 1200 kg | 1640 kg | 1950 kg |

Optional Features

| Option | D4025S | D4032S | D5042S |

|---|---|---|---|

| Single-Operator Use | ✓ | ✓ | ✓ |

| Pre-Roll Sweeping Unit | ✓ | ✓ | ✓ |

| Automatic Rolling System | ✓ | ✓ | ✓ |

Note:

All models operate on 380V / 50Hz Three-Phase power as standard.

Models compatible with 60Hz can be manufactured upon customer request.

A carpet beating and dry-soil removal machine is not an optional accessory

it is a critical pre-wash component for every professional carpet-cleaning operation.

1. Because 70-80% of carpet soil is dry particulate and it does not dissolve during washing.

Scientific studies show that the majority of soil in carpets consists of dry dust and particulate matter.

These particles do not break down during wet washing; instead, they mix with water and turn into mud, making the washing cycle longer, less efficient, and more chemical-intensive.

A beater machine removes this load before washing begins, dramatically improving the entire process.

2. It significantly reduces water and chemical consumption.

The less dry soil a carpet contains, the easier it foams and rinses inside the washing machine.

This translates directly into:

Up to 20% water savings,

Lower shampoo usage,

Reduced energy consumption.

Few technologies lower operational costs this effectively.

3. It speeds up washing and reduces rinse cycles.

A carpet free of embedded dust washes faster, rinses quicker, and moves through the line more efficiently.

Daily capacity increases without additional labor.

4. It opens the fibers for deeper, more uniform cleaning.

The machine does more than remove dust;

it loosens the warp and weft fibers, lifting the pile and allowing detergents to penetrate deeper.

The result: visibly cleaner, brighter carpets with restored texture.

5. It shortens drying time.

With less dry soil inside, the carpet holds less water during washing.

This accelerates extraction, spinning, and drying, reducing total cycle time and energy usage.

6. It lowers the rewash rate.

Carpets not properly dust-released often require a second wash.

The beater machine eliminates this problem, reducing workload and improving operational efficiency.

7. It is a quality standard for modern professional facilities.

In contemporary carpet-cleaning plants, a beater machine is considered an essential part of the washing line.

It ensures higher customer satisfaction, lower costs, faster throughput, and a more sustainable operation.

In Summary: Why is this machine necessary?

Because it enables cleaner, faster, and more efficient washing with less water, fewer chemicals, and lower energy consumption.

It reduces costs, increases quality, and strengthens environmental sustainability.

RELATED PRODUCTS

Blanket and Quilt Washing Machine

Brendo Otomatik Tente Yıkama Makinesi

Mega Automatic Carpet Washing Machine

Offering belt widths of 250-320 cm and a washing capacity ranging from 500 m² to 1650 m² per 8-hour shift, the Mega series is a durable, efficient, and scalable machine for growing businesses.

Sage Carpet Spin Dryer Centrifuge Machine

✅ 1300 RPM high-speed spin for quick water extraction

✅ Silent and vibration-free bellows suspension system

✅ Pneumatic lid with easy-lock safety mechanism

✅ Spheroidal graphite cast iron lid – built for decades of trouble-free use

✅ Automatic braking system with timer-controlled panel

✅ Soft-start support – reduces energy consumption

✅ Stainless steel inner drum – hygienic and durable

✅ Optional inverter control panel and multiple size options

🔹 With this machine, your carpets don’t just dry fast — they dry flawlessly!